We do 100% Quality Assurance on production line for all of our Watch Winders. As well as we inspect every piece of our Watch Winders before packaging.

Example of Internal Quality Control procedure for DC Series:

- 1. Appearance of Wooden Housing:

- Checking the quality of Wooden Housing piece by piece. Reject the housing with visible scratches.

- 2. Finished Goods Inspection/Testing:

- a. Basic Set Up: Before testing, set up the testing winder as follows:

- Direction Switch: Put the toggle on the left position (Automatic Reversing).

- TPD Switch: Set the TPD to Program: 3,600/Interval 24 sec.

-

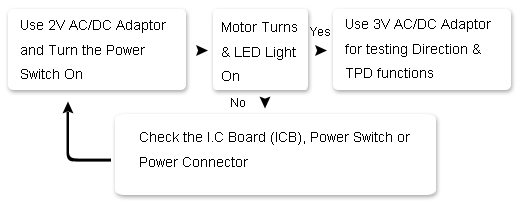

b. Mechanism-Functions Testing:

Power Supply from AC/DC Adaptor & LED Light Checking-

- 3. Quality Checking while Assembling:

- Screwing the Power connector into the brass cap which fit with wooden box. Plug in the Power connector on ICB. Checking the motor turns or not. If the motor turns, screwing it into mechanism with wooden housing. Otherwise, change the Power connector.

- 4. Solution:

-

If tested result was not acceptable, then checking steps as follows:

- Checking if the connecter of switch corresponds with the correct position on IC Board.

- Changing the relative components.

- 5. Final inspection before packaging:

-

- Our Quality Inspector will check the Direction Function (I, O, II) before packaging.

- TPD program is set to 3,600 turns/interval 24 sec. while packed.

- If Watch Winder works fine and pass our quality control, then the goods will go for final cleaning before packaging.

- Any other problems being found at this stage, will be returned for double checking at beginning.

Direction & TPD Checking

Step 1

ON  (II: Automatic Reversing)

(II: Automatic Reversing)

3,600/24 Sec.

From Start To Next Start 24 Sec.

- Turn on the Power Switch On, motor will turn randomly. Checking the direction of the 1st turn is Clockwise. The motor stops after the 1st turn.

- The motor will turn again soon. Checking the direction of the 2nd turn. The direction has to be the Counter Clockwise and at the same time, use a timer for double checking the Interval.

- Checking if the interval is 24 seconds when the motor turns again and the direction is clockwise again.

Step 2

ON  (I: Clockwise)

(I: Clockwise)

2,880/ 30Sec

From Start To Next Start 30 Sec.

- Put the direction switch to “I” (Clockwise).

- Put the TPD switch to the above program.

- Check the direction and TPD when the motor turns. Checking if the interval is 30 seconds when the motor turns again.

Step 3

ON  (O: Counter Clockwise)

(O: Counter Clockwise)

2,107/ 41 Sec

From Start To Next Start 41 Sec.

- Put the direction switch to “O” (Counter Clockwise).

- Put the TPD switch to the above program.

- Check the direction and TPD when the motor turns. Checking if the interval is 30 seconds when the motor turns again.

Direction Testing will be completed at this stage

Step 4

ON  (O: Counter Clockwise)

(O: Counter Clockwise)

1,150/ 75 Sec

From Start To Next Start 75 Sec.

- Put the TPD switch to the above program.

- Checking if the interval is 75 seconds when the motor turns again.

Testing Completed.